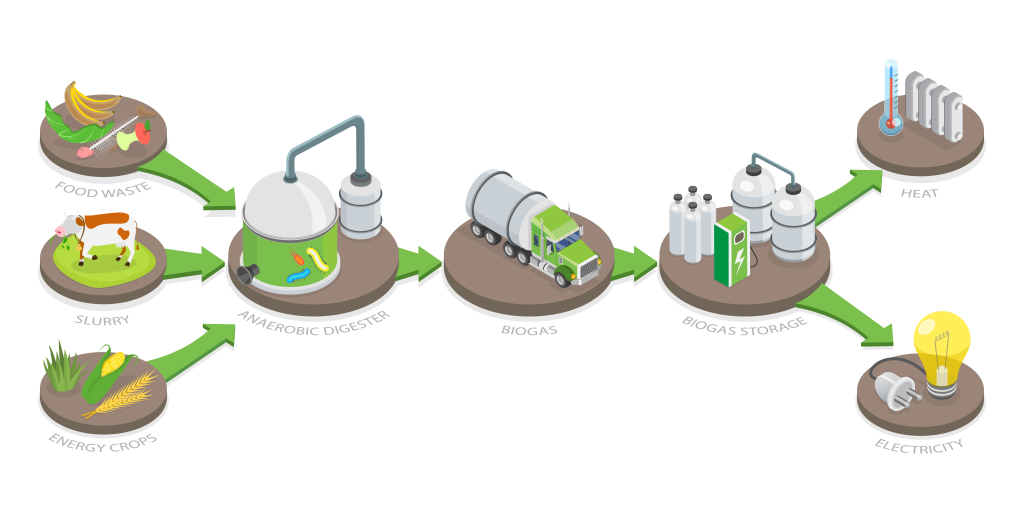

Anaerobic digesters receive fresh manure daily from the livestock facility in which the

animals are fed & housed. Anaerobic microbes (that thrive in an oxygen free environment) & ferment feed within the cow’s stomachs are transferred with manure daily continuing this fermentation activity on any non-digested feedstock, excreted by the animal & delivered into the digester. Pre-consumed off-farm organics may be added to the digester to degrade from this on-going fermentation process and add exponentially to energy production. The volatile gases bubble to the surface, accumulate & are captured under the inflated vinyl digester covering from where it is collected. This collected gas has a composition that is approx. 60%-65% methane (CH4) and 35% carbon dioxide (CO2) plus small amounts of water(H2O), hydrogen sulphide (H2S), VOCs and a trace number of unwanted elements & contaminants. Biogas can directly power a Combined Heat & Power (CHP) Engine specially built to operate on this CO2 & CH4 gas mixture provided we remove water and sulphur dioxide to acceptable levels. CHP engines normally power generators that produce electricity to supply production site electrical, meet any farm and/or off-site electrical needs of local existing industrial/commercial user/s or connected & sold to a local electrical utility distributor grid for their customers use in heating homes, fueling transportation or embedded regional gas-powered electrical energy generation hubs.